Cotton Fabric Mercerization

Mercerisation is one of the most important processes of finishing cotton materials. It imports gloss to the fibre, increases its hygroscopicity, strength and improves its dye affinity.

The mercerising process consists in treatment of cellulosic materials with concentrated solutions of caustic soda at a temperature of 15 to 18°C. Mercerised cellulose is hydrated cellulose, i.e., a product which from the chemical point of view, is identical to the original cellulose, but differing from it in physical properties.

This method was patented in 1850 by the English calico printer John Mercer and hence forth this process has been called as mercerisation.

Under the action of concentrated alkaline solutions chemical, physico-chemical and structural modifications of cellulose take place. Chemical reactions lead to the formations of alkali cellulose, physical reactions, to intensive swelling of fibres and structural reactions, to a change in the arrangement of units in the cellulose macromolecule.

Concentrated solutions of caustic soda cause considerable swelling of cotton fibre, the changes in cellulose physical properties being irreversible. When the fibre swells, its volume undergoes considerable changes; at maximum water absorption, the cross section of cotton fibre is increased by 40 to 50% with inconsiderable increase in length (about 1 to 2%).

The size of pores in the fibrous ,material is considerably increased.

The main factors influencing the factors of selling are temperature of treatment, the concentration of the alkali in the solution and additions made to the solution.

Cellulose swelling in an alkaline solution increases with a drop of temperature.

Alkali concentration is also of great importance for the cellulose swelling. The greatest swelling of cotton cellulose is observed at alkali concentrations characterized by an appearance of an X-ray pattern of an alkali cellulose.

At which stage cellulose can be Mercerised?

Mercerisation is possible

- on greige goods

- after desizing

- after desizing and scouring

- after bleaching

- after dyeing.

Woven fabrics are mercerized in full width, knitted fabrics in full width or in rope form.

The sodium hydroxide concentration varies from 20% - 30%.

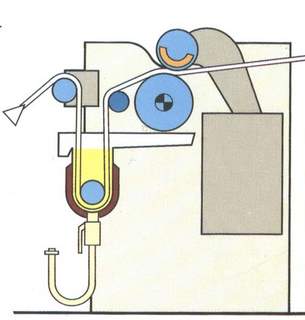

The process, done in a continuous way, consists of the following steps:

- padding of the textile with the lye

- drafting of the textile

- washing (under tension)

- acidifying, rinsing.

The main ecological impact in mercerising is the high concentrated residual lye.

Causticizing (alkali treatment):

Similar effects to mercerising can be achieved by the Causticizing process. Causticizing in comparison

to mercerising is done without tension stress on the textile at temperatures between 10 °C and 15 °C.

The process induces shrinking of the textiles. Ecological impacts in Causticizing can be compared to mercerising.