The World's Strongest Stuff

- By Melissa Salpietra

- Posted 11.24.10

- NOVA

Ask a materials scientist to choose the strongest material, and you are likely to get a question instead of an answer. What kind of strong? Tensile strength? Toughness? Yield strength? Hardness? When it comes to materials, there isn't a single definition of strength but rather ways to measure certain characteristics. And each material can be strong in some ways and weak in others. If you build a bridge out of glass, it may be able to hold a heavy load, but if a boat passing underneath were to strike it, it might shatter. Some materials, however, rate relatively highly in several strong characteristics, as the sampling below demonstrates.

Diamond

Unmatched in its ability to resist being scratched, this much-loved gemstone ranks the highest in terms of hardness. Diamond is a naturally occurring ceramic made of carbon atoms strongly bound together in a lattice. It is used in drill bits, sandpaper, and saws to cut, grind, and polish. Although it holds the hardness record, diamond is not tough—if you smash it with a hammer, it will fracture and break.

Diamond, pictured here in an uncut, unpolished state, is the hardest known material. Enlarge Photo credit: © ProArtWork/iStockphoto

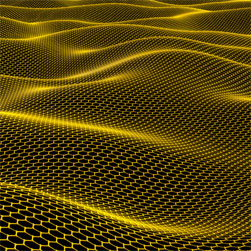

Graphene

Made up of carbon atoms, graphene is a nano-cousin to diamond that forms a super-thin sheet only one atom thick. This may sound ultra-delicate, but the force required to break it is very high—higher than that necessary to break steel. As strong as this human-made material is, it is challenging to manufacture, and it can’t be mass-produced yet. In the meantime, graphene is getting attention for other impressive characteristics, including its potential in data and energy storage.

Graphene is a one-atom-thick layer of carbon arranged in a chicken-wire pattern. Enlarge Photo credit: © Pasieka/Photo Researchers, Inc

Maraging steel

Maraging steel is a member of the super-strong steel family. It is an alloy—a mixture of metals—that is heat-treated, a process that makes it very hard and tough. Maraging steel also has the ability to withstand pulling forces, or tension (tensile strength). It can absorb a lot of energy before it deforms. And even when it does fracture, it won’t break right away (fracture toughness). Finally, it can retain these talents at higher temperatures than most steel, a desired trait for use in high-performance engines and other aerospace applications.

Spectra® fiber

Plastic comes in all shapes and sizes, but in terms of strength, high-performance polyethylene takes the cake. This plastic is made of extremely long molecules stretched out alongside one another that bond together very tightly. Manufacture these molecules into fiber and you have Spectra®, a lightweight, tough thread that can withstand an immense amount of tension—it is five times stronger than steel on a weight-to-weight basis. These fibers can be used in everything from bullet-proof vests and armor to high-tech sports gear and sailcloth.

Spider silk

Both lightweight and tough, this biopolymer has been getting a lot of attention lately because of its high tensile strength. A thread of silk can resist more pull before breaking than a thread of most kinds of steel. It is also quite stretchy. In the spotlight recently has been the newly discovered Darwin’s bark spider of Madagascar, which builds one of the largest webs known. The silk of this spider is twice as strong as other spider silks, ranking it among biological materials with the highest tensile strength and toughness known.

The web of a Darwin’s bark spider, seen here, is one of the toughest biological materials yet discovered. Enlarge Photo credit: © Lalueza-Fox, C.; Agnarsson, I.; Kuntner, M.; Blackledge, T. A.

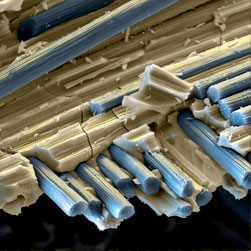

Carbon/carbon composite

What do you get when you put ultra-strong carbon fibers within a super-strong carbon matrix? A carbon/carbon composite. There are many different types of such composites, and all have different properties depending on how the fibers lie in relation to the matrix. But carbon/carbon composites in general have a slew of strong properties. They can resist an immense amount of tension, and they can absorb a lot of force before cracking (toughness). And because they are lightweight, these composites are particularly useful to aerospace engineers. High-performance aircraft like the B-2 bomber use them, and they are also found in the skin of space shuttles and in the nose cones of Intercontinental Ballistic Missiles.

This B-2 bomber gets its strength, in part, from carbon/carbon composites. Enlarge Photo credit: © telegraham/iStockphoto

Silicon carbide

Made of silicon and carbon, this ceramic is found in meteorites in small quantities. Fortunately, manufacturers here on Earth have also been able to produce it commercially. This material almost matches diamond in its hardness, but it surpasses it in its toughness. Silicon carbide is used in grinding tools, sandpaper, and brake discs, to name a few applications. It is also the basis for Chobham armor for battle tanks—an armor so effective that not one British Challenger tank was destroyed in Operation Desert Storm.

A scanning electron microscope image of a carbon/carbon composite composed of fibers (in blue) and silicon carbide (in brown) Enlarge Photo credit: © Eye of Science/Photo Researchers, Inc

Nickel-based super-alloys

In engineering, simply being strong at room temperature doesn't always cut it. Materials need to be able to withstand extreme situations. High heat is one circumstance that nickel-based super-alloys can handle. Composed of nickel, aluminum, titanium, and a complex soup of other elements, these metallic alloys are strong and tough. But more importantly, they retain these strong qualities at very high temperatures. Where most metals or alloys lose strength in high-heat situations, nickel-based super-alloys aren't affected until they reach close to their melting point, which makes them the perfect material for turbine blades and discs for jet engines.

Turbine engines contain nickel-based super-alloys, which can withstand high temperatures. Enlarge Photo credit: © sndr/iStockphoto

Related Links

-

Making Stuff: Stronger

David Pogue tests his mettle against the world’s strongest stuff, from steel and Kevlar to bioengineered silk.

-

Materials That Changed History

From ceramics to steel, paper to plastics, certain basic substances have long propped up civilization.

-

Nature’s Super-Materials

See some of Nature's stickiest, toughest, and cleanest materials, and learn how they are inspiring new products.

-

Making Stuff: Series Overview

Technology reporter David Pogue hosts a four-part special series exploring the materials that will shape our future.